The Importance of Afterburners on Larger Coffee Roasters

In the world of coffee roasting, precision and quality are paramount. As roasters scale up their operations to meet increasing demand, they encounter a host of new challenges, one of the most significant being the management of emissions. This is where afterburners come into play, becoming an essential component for larger coffee roasters.

In the world of coffee roasting, precision and quality are paramount. As roasters scale up their operations to meet increasing demand, they encounter a host of new challenges, one of the most significant being the management of emissions. This is where afterburners come into play, becoming an essential component for larger coffee roasters.

But are afterburners really necessary, especially in states they are not required by law? Some manufacturers will tell you they are not, but afterburners do more than just keep your business compliant. Coffee roasting in large batches can be a dirty game, without an afterburner.

The Role of Afterburners

An afterburner is a secondary combustion device installed in coffee roasting systems to incinerate volatile organic compounds (VOCs), particulate matter, and other pollutants released during the roasting process. The roasting of coffee beans generates a substantial amount of smoke, odor, and potentially harmful emissions, particularly when roasting in large volumes. Afterburners effectively reduce these emissions, ensuring that the roasting process is not only more environmentally friendly but also compliant with air quality regulations.

Key Benefits of Afterburners

- Environmental Compliance

Regulatory Requirements: Many regions have strict air quality regulations that mandate the reduction of industrial emissions. Afterburners help coffee roasters comply with these regulations by significantly reducing the release of pollutants into the atmosphere. This compliance is not just about avoiding fines and legal issues; it’s about demonstrating a commitment to environmental stewardship. - Odor Control

Minimizing Nuisance: The roasting process produces strong odors that can be a nuisance to neighboring communities. Afterburners effectively neutralize these odors by burning off the organic compounds responsible for the smell, making the roasting operation more community-friendly and reducing complaints from nearby residents and businesses. - Health and Safety

Reducing Harmful Emissions: VOCs and particulate matter released during roasting can pose health risks to workers and the surrounding community. By using afterburners, roasters can ensure a safer working environment and contribute to the overall well-being of their community by reducing the presence of these harmful emissions. - Improved Product Quality

Consistency and Cleanliness: The presence of smoke and particulates can affect the flavor and aroma of the coffee. By removing these elements, afterburners help maintain a cleaner roasting environment, which can contribute to more consistent and high-quality coffee products. This is particularly important for specialty coffee roasters who prioritize the subtleties of flavor and aroma in their beans.

How Afterburners Work

Afterburners operate by introducing the exhaust gases from the roasting process into a high-temperature chamber where they are burned again. This secondary combustion process typically occurs at temperatures between 1,200°F and 1,500°F (650°C and 815°C). The high temperature ensures that VOCs and particulate matter are incinerated, resulting in cleaner emissions. The key components of an afterburner system include:

- Burner: Heats the chamber to the required temperature for effective combustion of pollutants.

- Combustion Chamber: The area where the exhaust gases are re-burned.

- Control System: Manages the temperature and flow of gases to ensure efficient operation.

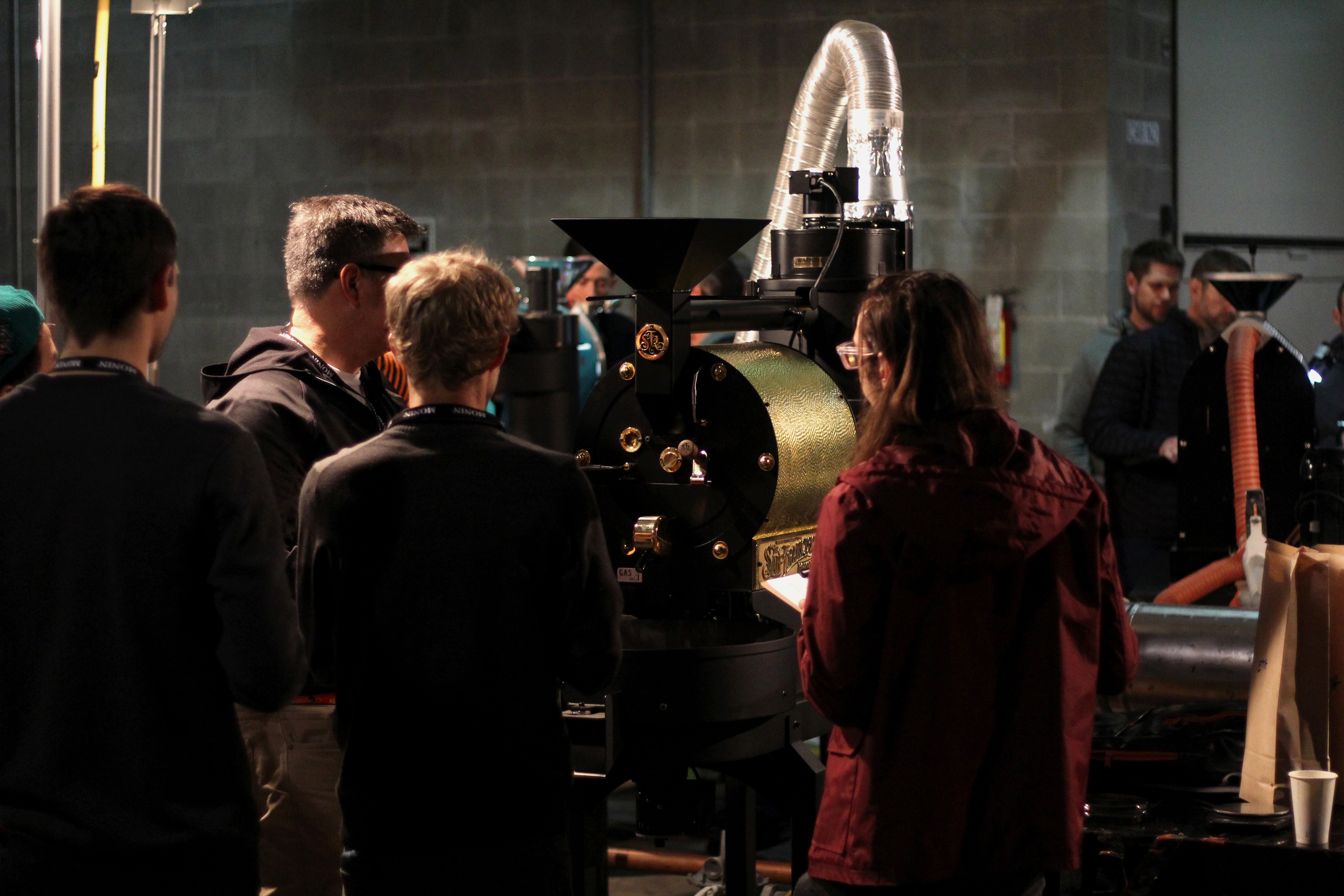

The San Franciscan Roaster Co.'s Commitment

At The San Franciscan Roaster Co., the integration of afterburners in our SF-25 and SF-75 roasting systems underscores our commitment to quality, safety, and environmental responsibility. Our equipment is designed to meet the highest standards, ensuring that roasters can scale their operations without compromising on these crucial aspects.

By using afterburners, we not only help roasters comply with environmental regulations but also enhance the overall roasting process, resulting in better coffee and a healthier environment. This dual benefit makes afterburners an indispensable tool for any serious coffee roasting operation looking to grow sustainably.

Conclusion

As the coffee industry continues to grow and evolve, the need for efficient, environmentally responsible roasting practices becomes increasingly important. Afterburners play a crucial role in this, providing a solution that addresses both regulatory requirements and quality concerns. For larger coffee roasters, investing in afterburner technology is not just a matter of compliance, but a commitment to excellence in every aspect of their craft.